Product Categories

- All

- Air Cooled Heat Exchangers

- Air-to-Air Heat Exchangers

- Indirect Heat Exchangers for Solids

- Cooling Towers

- Direct Fired Heaters

- Electric Heaters

- Electric Heating Elements

- Finned Tube Coils

- Hairpin, Double Pipe Heat Exchangers

- Heat Exchanger Service and Parts

- Heat Recovery

- Indirect Fired Recirculating Gas Heaters

- Industrial Duty Electric, Steam and Glycol Heaters

- Mist Eliminators

- Pipeline Heating Systems

- Plate Coil Sections and Assemblies

- Plate & Frame Heat Exchangers

- Scrubbers and Thermal Oxidizers

- Shell and Coil Heat Exchangers

- Shell and Tube Heat Exchangers

- Spiral Heat Exchangers

- Thermal Fluid Systems

Heat Exchanger Service and Parts

Our partners provide heat exchanger service and parts in the following areas.Shell and Tube Heat Exchangers: CMS Heat Transfer Division, Inc. (CMS) |

||

New and Replacement Bundles: CMS manufactures a variety of new and replacement bundles in all sizes and construction materials, from 4" x 24" to 54" x 30' long. |

||

|

A CMS 1142 60" x 24' long all carbon steel skeleton assembly with over 1600 1" diameter tubes in the process of being repaired |

|

Repair and Refinishing: Fouling and corrosion decrease a heat exchangers efficiency and lead to expensive downtime. CMS offers repair and refurbishing of most standard units. |

||

|

|

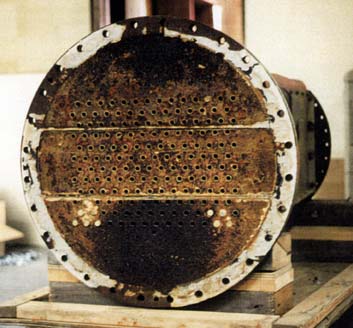

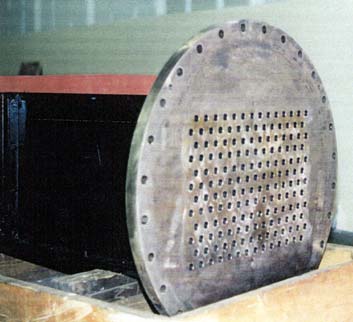

Photos of a CMS 1003 air compressor intercooler before and after emergency reconditioning CMS salvaged and refinished the original tubesheets and side casings, and refit the unit with new CuNi fin tube and stainless steel hardware |